Pacific Transformation LLC

Seattle, WA

Welcome

Contact Dave at 206-841-1558, or

dave@pacificcrafted[dot]com

[website under renovation]

Dave Wemer

Hi – I’m Dave Wemer, and I am Pacific Transformation, located in Seattle Washington!

I’m about change, diversity of projects and experiences, and the expansion of self via craft.

I’m a student by nature and someone who likes working with his hands. My education spans design to engineering, and the liberal arts to business.

I started my career managing large complex commercial construction projects. I made my way to carpentry, and find the finishing aspects of building the most satisfying.

The engineer in me appreciates attention to detail and sees the details as necessary to make all the elements of a project come together cohesively. The designer within appreciates standing back and permitting the feel of all elements in a space to connect with one another.

Thanks for visiting my site – I can be reached at (206) 841-1558 or dave@pacificcrafted[dot]com.

Projects/Work

Do you need – something built, modified, repaired, remodeled, altered, or changed? I’m not focused on large whole house remodels or custom homes; I’m focused on those projects which are smaller and more intimate, and equally complex. As a carpenter, I aim to build with wood.

Finish carpentry grabs me, and thus I enjoy focusing on interior finish work. But that doesn’t limit what I can or am willing to perform.

If you would like to reach me send me an email at dave@pacificcrafted[dot]com. Email is a preferred way to reach me. If you would like to call, I can be reached at 206-841-1558.

Remember – I’m managing your project; and I’m the one onsite who will perform the majority of the work if not all of it. I will be the one you will work with as you make the change you seek to make.

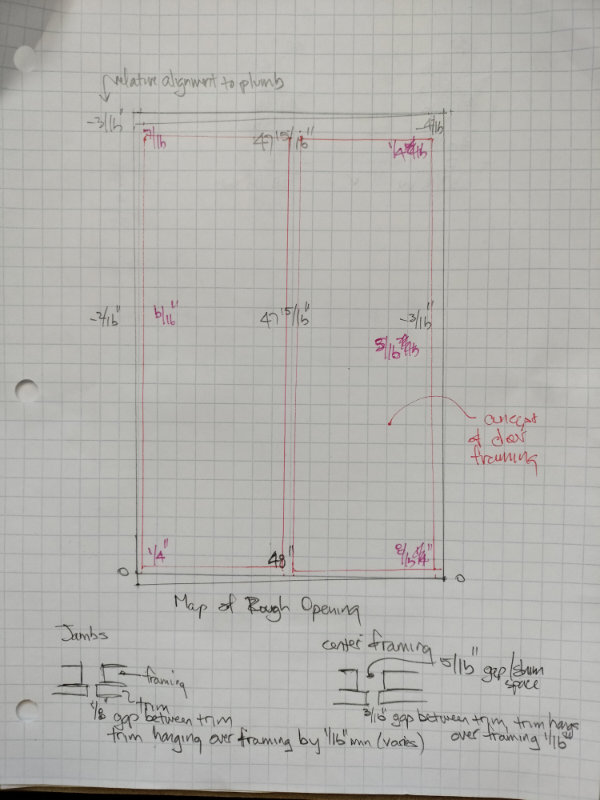

Highlighting Complexity Amidst the Seemingly Simple

What you are about to witness isn’t about something small, but rather something complex.

It turned out nice. It looks clean and simple. It wasn’t. Notice the nice reveals between the doors – between the trim. This didn’t happen by accident. It was planned, complex to create, and required a lot of craftiness. Let me take you behind the curtain and illuminate a few of the details.

This project was not built in a climate controlled factory with precise CNC machinery. It was built the old fashion way – paper, pencil, lots of thought, plenty of math, and lots of care with the right tools.

My first order of business was to map the existing framing and determine how square and plumb it was. It wasn’t; but it also wasn’t that bad. Then I needed to identify the narrowest points that would still allow for plumb and square doors to be built. Next, I worked backwards from the final finished trim, back through the plywood sheathing and lastly to the framing of the door.

The door frames were built on the ground, shimmed together as one unit, hung in the opening to ensure they would fit; measured to a string line which identified the centerline of the opening. Once assured the frames would fit in the opening, they were removed, clad in sheathing and trim, and then installed – held in place by clamps, until hinge locations could be identified and installed.

Next, trim was applied to the building. The hinges located so they would align clear and straight and function uniformly. Remember how the existing building frame was not plumb and in alignment. Each hinge needed to align with the other hinges and not with the building. The alignment and installation of the hinges required thought and a little TLC….

When it was all done, the doors had clean reveals, functioned well, and hid the existing framing that was out of alignment.

When you look at the picture you see a clean and simple shed. But, in reality, this re-build was anything but simple. Now that other project, the big one, which I too renovated, was also equally complex.

Let me help you decipher your projects complexity.